Die Casting Services China

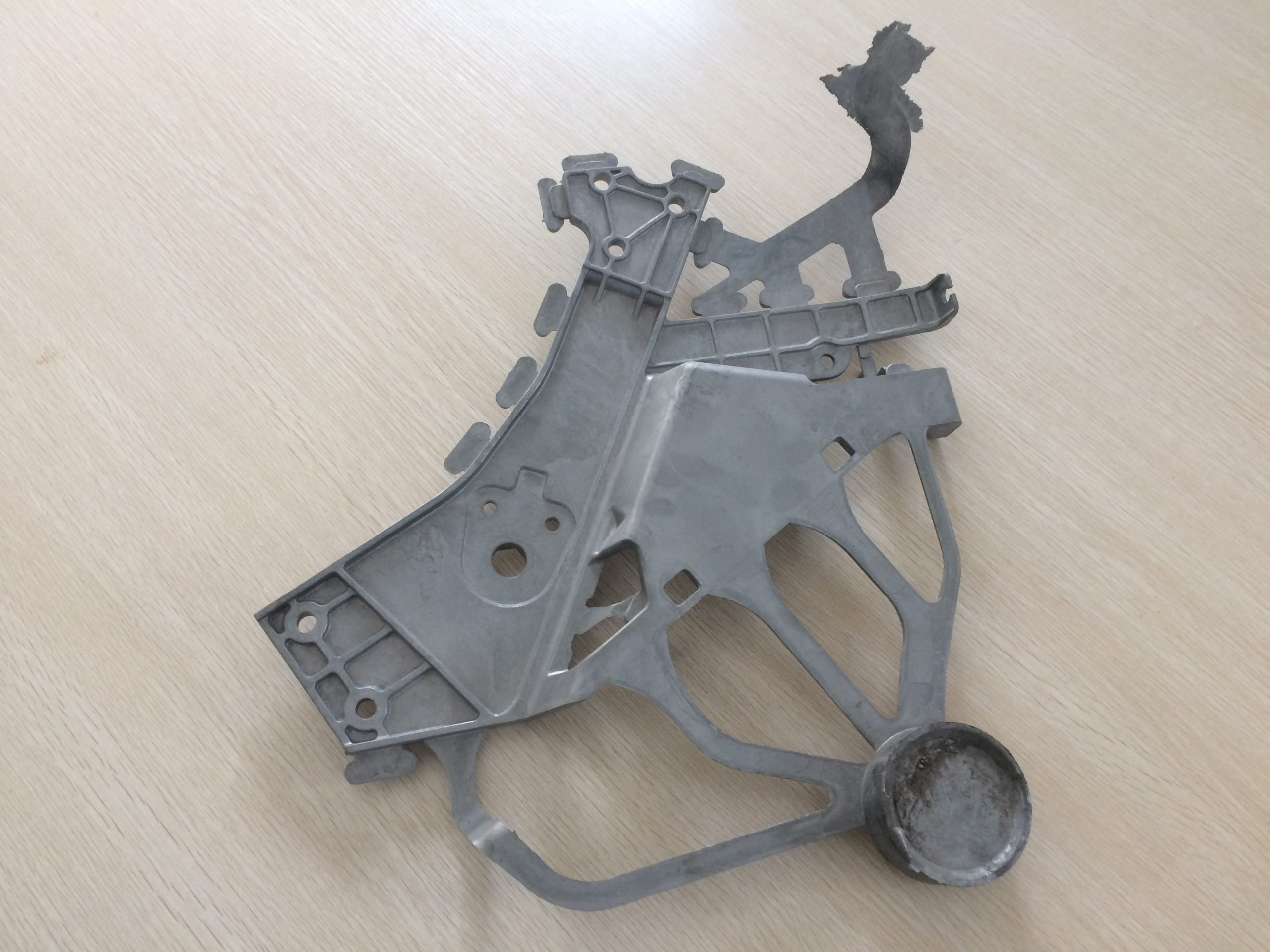

Die Casting Services China: Die Casting is one of WeLink main services, it is born in the early years when WeLink was built. After 10 years developing, WeLink has rich experience in Aluminum Alloy & Zinc Alloy Die Casting. We make die casting molds and parts for Automotive, Industrial, Door-Window, Bathroom, Kitchen and more products.

WeLink Die Casting Services

WeLink can construct tooling in a variety of sizes and shapes, ranging from simple parts to the complex geometry. With our comprehensive tool and die making capabilities, we can provide single and multi-cavity dies, as well as complete interchangeable cavities for standardization and repeatability in large multiple die programs.

The experience in WeLink Die Casting Team is the most precious and warranted for both success and lower cost. The most appropriate materials, die design, DFM, tech and process are the keys why WeLink has been trusted by Kin Long for decades of years. Also Read our die casting China services on WeDieCast. For more details about our manufacturing capacity please visit our single web: Die Casting Services China

What Is Pressure Die Casting?

Pressure die casting is the process of making high fidelity copies of your designs by injecting molten metal into custom made steel dies. It’s the most cost effective way to produce medium to high volumes of metal parts with excellent surface finish and dimensional accuracy.

Advantages Of Die Casting

- Castable metals include aluminum, zinc and magnesium

- Mold tools can make tens of thousands of parts economically

- Surface finish and accuracy are excellent

- Complex geometries can be achieved

- Especially suited for larger metal parts

Pressure Die Casting Tolerances

We follow the standard general NADCA tolerances. However, if your requirements are very precise, then the precision tolerances standard can be followed once we have confirmed your designs.

Pressure Die Casting Materials

Mold Tools

Our mold tools are usually made from H13/1.2344 tool steel with a Rockwell hardness of 50-52. Specialty steels are available upon request. Read more about our export tooling service.

Die Cast Parts

Different metals are available for casting. Your choice of materials may depend on cost, weight and performance. Here are some tips:

- Aluminum is ideal for strong, lighweight yet complex geometries. It can also be highly polished. Our alloys include ADC12, A380, ADC10 and A413.

- Zinc is the least expensive but is good for plating. Available alloys are Zinc #3 and #5.

- Magnesium offers the best strength-to-weight ratio for higher performance applications. We offer magnesium alloy AZ91D.