Mold Making

Mold Engineering: DFM, Mold Flow, Design. Automotive molds, 2K molds, 2KT molds, 2K index plate molds, and multi-cavity hot runner molds.

Injection Molding

20+ Haitian injection molding machines from 120T to 480T. ABS, PC, PC/ABS, PA6+30%GF, PA66+50%GF, PS, PP, PVC, POM, TPE, TPU, TPV are available.

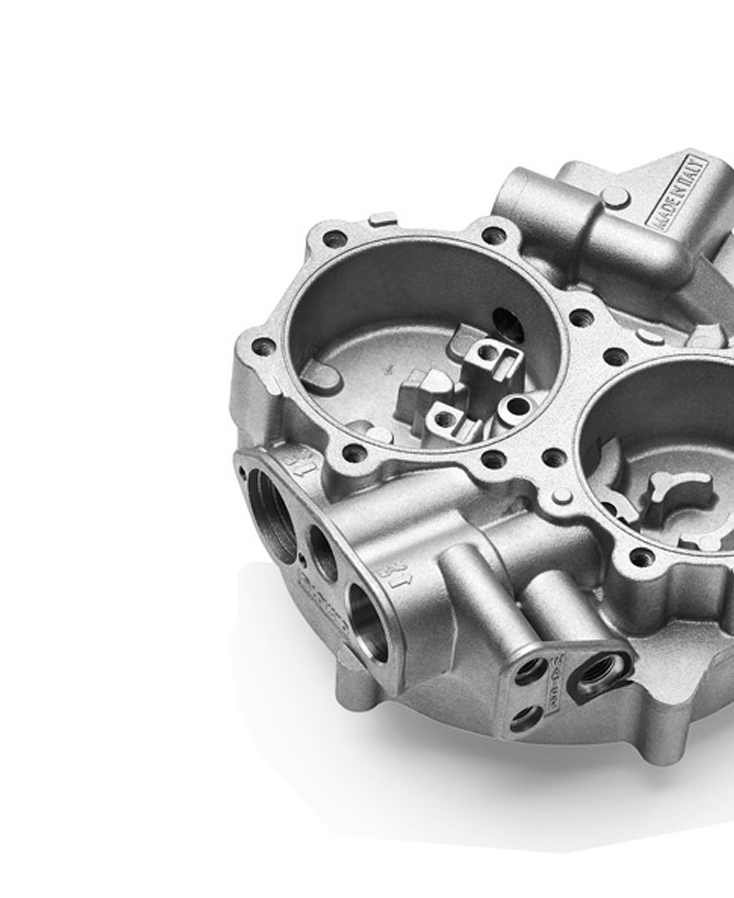

Die Casting

10+ LK die casting machines from 80T-600T. Alunimum & Zinc die casting + CNC machining + sand blasting, anodizing, planting, powder coating, electroplating.

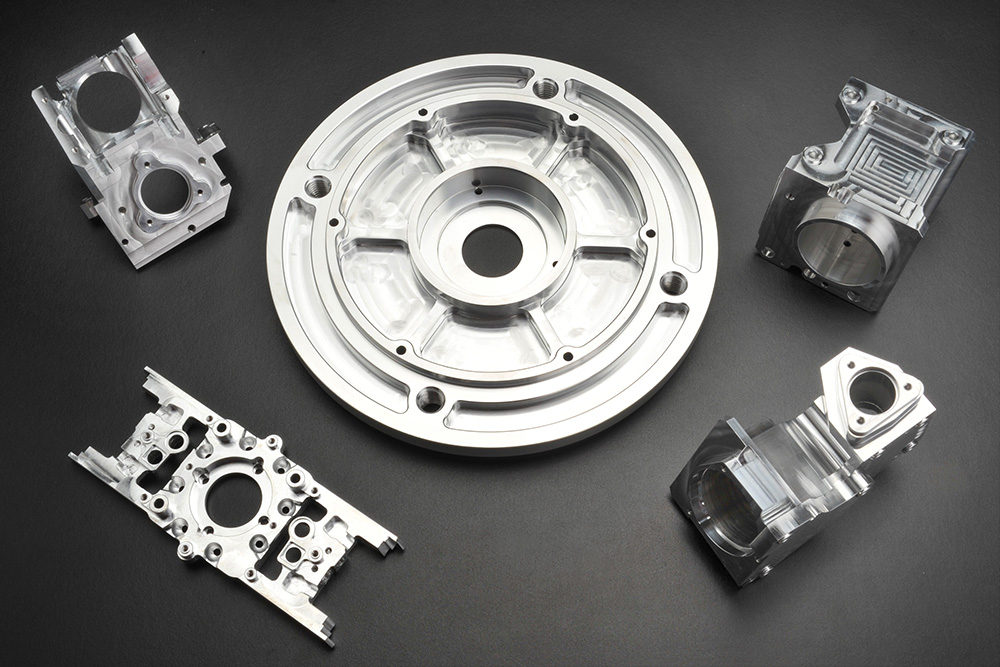

Prototyping

Rapid prototyping is another key service at WeLink. Our wholly-owned subsidiary ProtoWe provides rapid prototyping services to our global clients. The services included:

- CNC Machining

- 3D Printing

- Vacuum Casting

- Sheet Metal