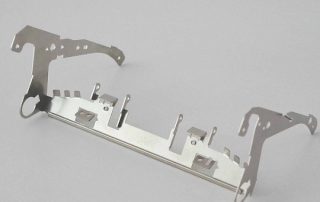

Metal Stamping Manufacturer China

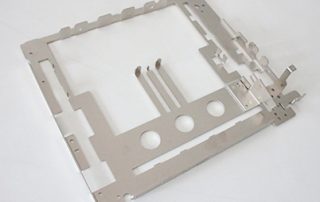

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques: blanking, punching, bending and piercing, to name a few. Metal stamping is a fast and cost-effective solution for this large-quantity manufacturing need. WeLink makes metal stamping for Aviation, Aerospace, Automotive, Construction,Transportation, Home appliances.

Capacity: Metal Stamping Manufacturer

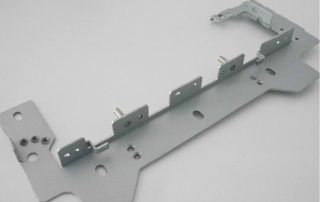

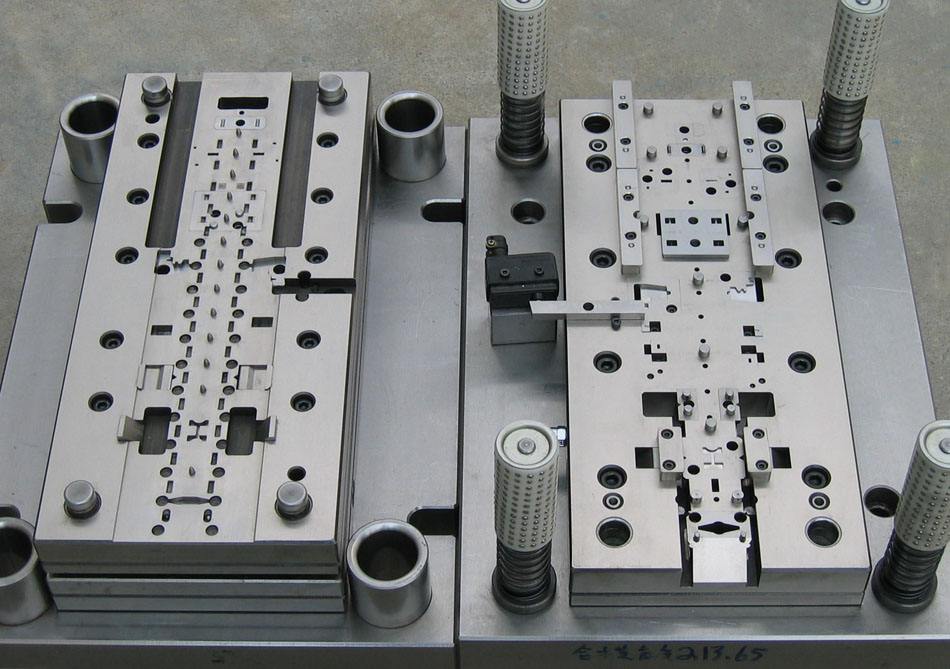

Progressive Die: These are utilized for high-volume production, and they are generally appropriate for high-speed operations. They offer an economical and efficient method of getting parts into production.

Compound Die: The compound die refers to a die structure in which a punch press completes multiple processes such as blanking and punching in one stroke. Compound die can manufacture large parts. Compared with single-process die, it can reduce the number of dies and improve stamping efficiency. In addition, reasonable compound mold design can also reduce mold cost.

Single-process Die: Single-process die refers to a die with only one station and only one procedure. It can be divided into punching die, bending die, drawing die, turning die and shaping die. Single-process molds make mold manufacture simple, easy to maintain, and can manufacture large parts. The disadvantage is that a complex part may require dozens of sets of single-process molds.

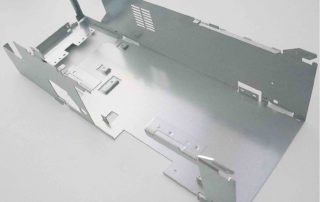

Short Run Stamping

Short run metal stamping requires minimal upfront tooling expenses and can be an ideal solution for prototypes or small projects. After the blank is created, WeLink uses a combination of custom tooling components and die inserts to bend, punch or drill the part. The custom forming operations and smaller run size can result in a higher per-piece charge, but the absence of tooling costs can make short run more cost-efficient for many projects, especially those requiring fast turnaround.

For more details about our manufacturing capacity please visit our single web: Metal Stamping Services