Non-Standard Custom Mold Components Supplier & Manufacturer China

Non-Standard Custom Mold Components Manufacturer China: WeLink is a global prime custom mold compoments supplier and manufacturer. Most clients have long term business cooperation with us that becsuse they are satisfied with our good and stable quality, short delivery time and friendly price.

Custom Components Manufactuing for Plastic Molds & Casting Dies & Stamping Dies

We are a one-stop custom mold compoments manufactuer of no-standard or easy damaged custom components for plastic injection mold components, casting die components & stamping die components. Our mold components are made with high quality and delivery woldwide in short time, DHL express to global clients. These components include but not limited to:

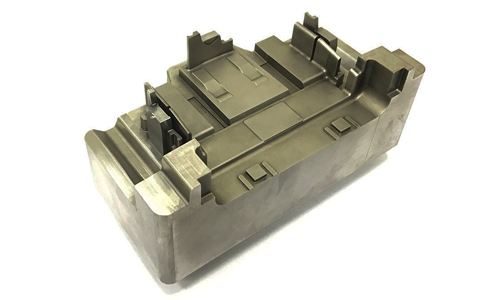

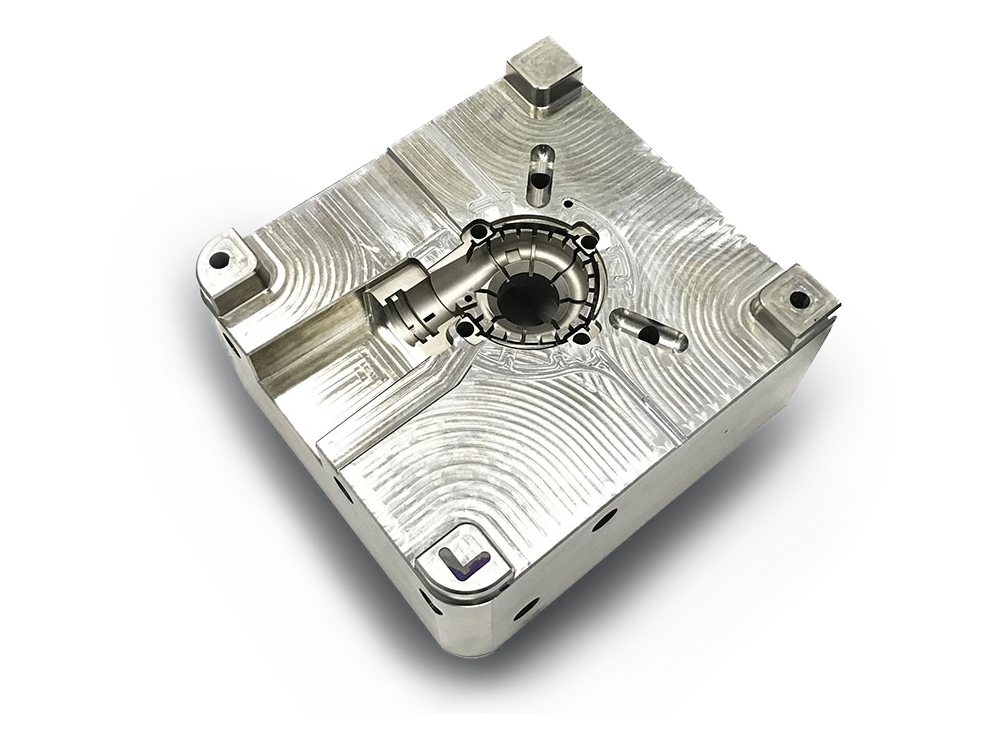

- Mold Cores & Cavities

- Mold Inserts/ Die Inserts

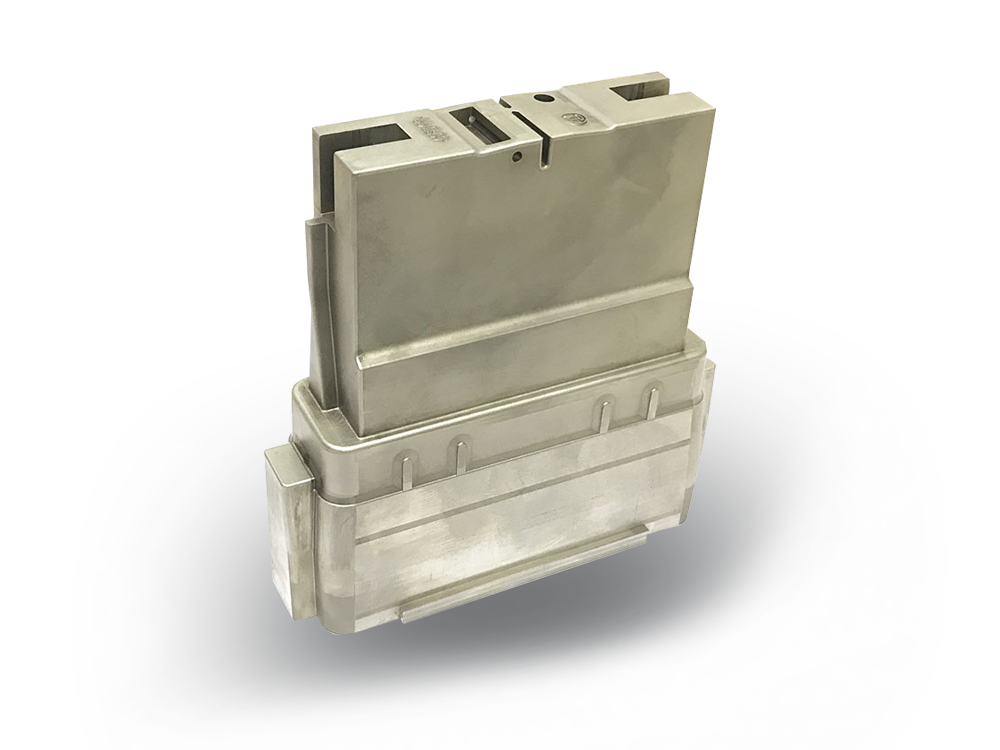

- Mold Sliders & Lifters

- Mold Ejector Pins

Mold Inserts

Sliders & Lifters

Ejector Pins

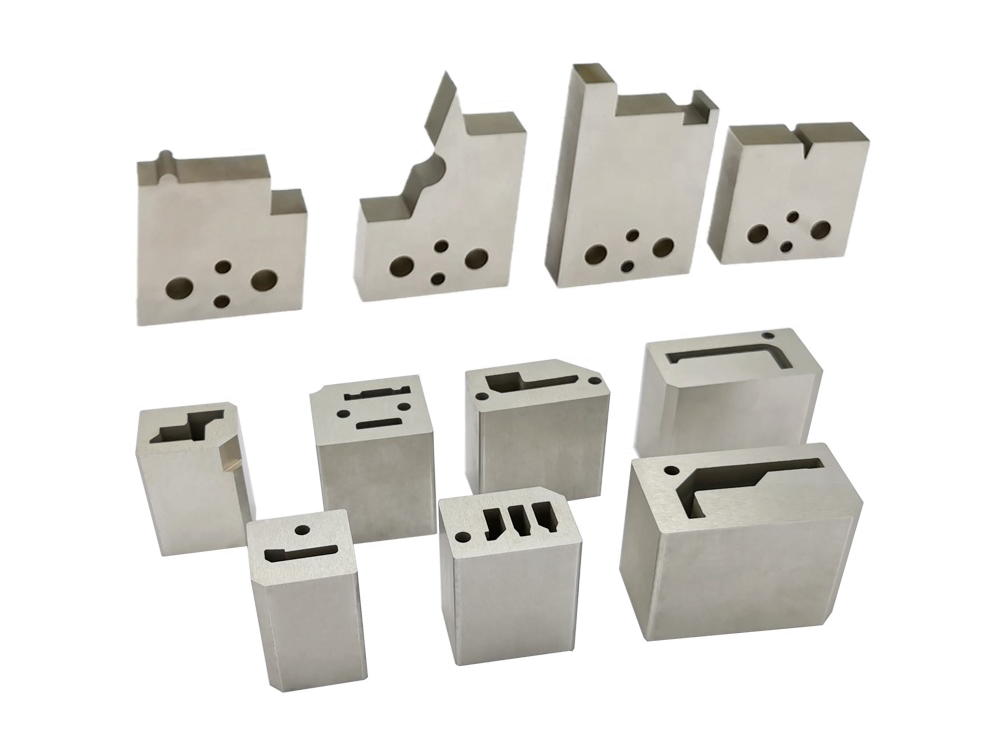

Stamping Die Components

Stamping Die Components

Stamping Die Components

Quality Control

At WeLink, quality is guaranteed. We have 2.5D & 3D CMM and a well-trained surveyor in our quality department. We provide FAI measurement reports for each part based on the tolerance requirement in the customer’s 2D drawings. Every part is delivered to customers with high quality.

WeLink also export high quality complete plastic injection molds. Just check it.

MAIN MECHINE LIST

| CNC Miller | CNC EDM | CNC Wirecut |

|---|---|---|

| 22 pcs | 16 pcs | 8 pcs |

| CNC Lathe | CNC Griner | Surface Grinder |

| 8 pcs | 9 pcs | 15 pcs |

| Electrode Carver | Miller | CMM |

| 18 pcs | 6 pcs | 3 pcs |

Proud of Quality & Value

Workshop Machines of Non-Standard Mold Components Manufacturing

How We Support Our Clients?

At WeLink, we well know quality and delivery time of the mold components are both very important for a mold project that made in our oversea clients. Different to a local supplier, if there were some defects on our mold components, our clients have no time to send back and repair. So we must focus on quality, make full inspections before shipping. Each mold component, we make dimensions report by 3D CMM, and provide steel material certification, heat treatment report etc.

We take care of each mold components project no matter it’s a big or small case. We care about clients’ deadline and promise the timing, even 2 shifts sometimes. 95% on-time delivery and 98% quality rate is our commitment to each client. As to pricing, always competitive, and stand by our clients as a long term and trusted business partner.