Low-Volume Machining & Turning Parts China

Low-volume machining & turning parts manufacturer China: WeLink is a global top custom low-volume production cnc machining & turning compoments supplier and manufacturer. Most clients have long term business cooperation with us that becsuse they are satisfied with our good and stable quality, very competitive prices, short delivery time and strong production capacity.

- 100+ cnc milling machines

- 50+ cnc turning machines

- Quality & on-time delivery

- Always competitive prices

Custom CNC Machined Components in Low-Volume Manufacturing

WeLink has a one-stop manufacturing solution for your any cnc machining or turning projects. These manufacturing services include rapid cnc machining prototypes, low-volume production cnc machining & turning services, and mass production cnc machining & turning services.

At low-volume machining & turning services, WeLink has the capacity of 100+ cnc milling machines, 50+ cnc turning machines for any custom machined parts requested by clients. A professional engineering team + a skillful operators team + a responsible QC team to ensure every project to be very efficiently running and quality & ontime delivery.

CNC Turning

CNC Milling

5 Axis Machining

Quality Control

At WeLink, quality is guaranteed. We have 2.5D & 3D CMM and a well-trained surveyor in our quality department. We provide FAI measurement reports for each part based on the tolerance requirement in the customer’s 2D drawings. Tolerance well meets ISO 2768-f, ISO 2768-m, ISO 2768-mK. Each part is delivered to customers with high quality.

Our advantages included but not limited to:

- 100+ cnc milling machines

- 50+ cnc turning machines

- Quality & on-time delivery

- Always competitive prices

Proud of Quality & Value

MAIN MECHINE LIST

| CNC Millers | CNC Lathers | CNC Griner |

|---|---|---|

| 100+ pcs | 50+ pcs | 10+ pcs |

| Surface Grinder | CNC W-EDM | CMM |

| 10+ pcs | 10+ pcs | 5+ pcs |

Low-Volume Machining & Turning Workshop

CNC Machining Surface Finishes

We offer in-house precision CNC machining surface finishes including:

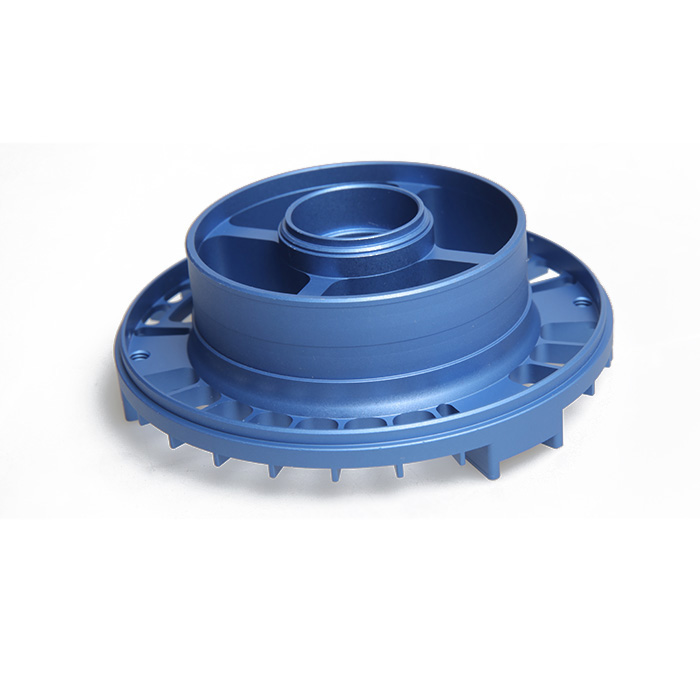

Anodization (Type II & Type III) – Anodization creates a layer of anodic oxide on aluminum, which provides corrosion resistance and durability, and can be used to change the color of the component.

Electroplating – Electroplating is used to add a thin, uniform layer of metal to a completed metal part.

Bead Blasting – Bead blasting uses tiny glass beads to create a uniform satin or matte appearance on the completed part for aesthetic purposes.

Polishing – Polishing is used to remove surface imperfections and buff the part or component to a mirror-like finish. surface roughness after polish is around RA0.01 μm-RA0.02μm.

Brushing – Brushing uses a fine, unidirectional grit to create tiny grooves in the metal component, leading to a unique appearance.

Laser engraving – Laser tools can be used to etch brand names, serial numbers and other information into completed parts.

Powder coating – Powder coating is used to add a layer of polymer paint, which enhances the appearance of the part and also adds durability and corrosion resistance.

As machined – This surface finish includes removal or sharp edges and deburring, but no further finishing. Tool marks will be visible. Typical surface roughness is around RA0.05 μm-RA0.1μm,