What’s Rapid Tooling and How it works?

What’s Rapid Tooling?

Rapid Tooling also called Prototype Tooling, is a rapid technology to make a simplified mold in the shortest time. It can get almost perfect molded parts as normal tooling and molding, but just take 5-10 days while normal tooling needs 30-40 days. As well as, cost 30-40% less.

Advantages of Rapid Tooling

- Rapid tooling is the process of building core and cavity inserts as a product of rapid prototyping technology. This process has got a number of merits including

- the product is brought into the market earlier than the scheduled time

- Developercan get the products at a lower price as compared to the price when products are mass produced using injection tools

- it facilitates the production of various products in a wider range of materials

- it lowers the time and cost of the product manufacture

- Rapid tooling is mainly used for specific small quantity needs including prototyping

- It may as well be used for troubleshooting existing problems

- Rapid tooling is being used these days to create molds for commercial operations since the time lag is so short between start to finish

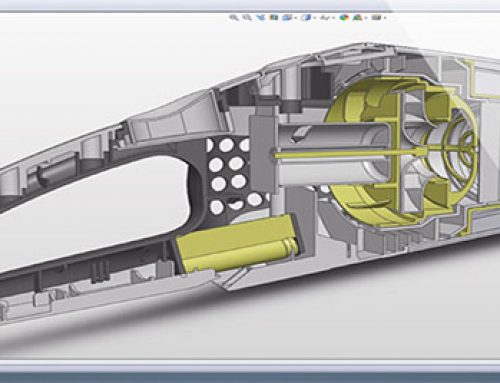

How Rapid Tooling Works?

There are many technologies used in Rapid Tooling, some are:

- Use standard and shared mold base. One mold base is used for many rapid tooling projects.

- Use easy cutting metal to make core/cavity and inserts, common metal is Aluminum, P20

- Simplify mold structure: no sliders and lifters, while inserts in instead, less other components

- cutting out extra processes such as EDM

- using low-cost components

- manual inserts

- 2-shift or 3-shift to make the mold 24h/7d.

Start A Rapid Tooling project with WeLink Toady!

Innovative Manufacturing Solutions China

for global medium-small companies

WeLink is a One-stop of Rapid Prototyping , Rapid Tooling, Export Tooling, Injection Molding, Die Casting, Metal Stamping, Rubber/Silicone. Rapid Prototyping includes SLA/SLS/SLM 3D Printing, CNC Machining, Vacuum Casting, Sheet Metal. We run fast and cost saved 50% than Europe & USA, 10% than China while in same good quality.

Request A Quote? email to quote@welinkgro.com

Request more support, contact our team >>