Structural Prototypes for New Product Development

The structural prototype is to make one or several products according to the structural drawings of the product without making a mold. The main functions of the prototype are as follows.

- Check the feasibility of the structure

The prototype is a physical object, which can be touched or assembled, which can intuitively reflect the rationality of the structural design, and can also be used to check the difficulty of assembly in order to find and solve problems in advance.

- Give customers an early experience of the product

After the prototype assembly is completed, it is a tangible product. You can experience the product in advance and propose modifications before the mold is opened. You can also let the customer use the prototype to do early publicity and promotion work, so that the product can be familiar to consumers as soon as possible, and thus occupy market.

- Used as a functional test

The development and testing of new products is indispensable, especially for electronic products. Functional testing must be repeated. Structural prototypes will come in handy. Structural prototypes can be used for testing before the mold is opened, which greatly shortens future testing. Time, so that the product will be listed in advance.

- Reduce the risk of direct mold making

For complex products, structural prototypes are especially important. Mold manufacturing costs are high, ranging from tens of thousands to millions. If unreasonable structural design is found between mold openings, mold manufacturing risks are greatly reduced, thereby reducing loss.

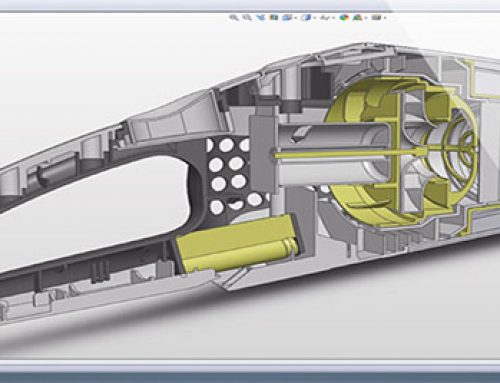

The production methods of structural prototypes currently mainly include 3D printing rapid prototyping (RP) and CNC machining center (CNC) processing.

Laser rapid prototyping is a kind of prototype manufacturing method that inputs three-dimensional drawings into a professional molding machine and piles up a little bit of plastic. The advantage is that it is convenient and fast. The disadvantage is that the surface roughness is low, it is difficult to handle, and the strength of the processed prototype is poor. , Small parts are difficult to process, etc.

The CNC machining center uses CNC machine tools to mill, turn, drill, and grind the raw materials to make products that are the same as the three-dimensional drawings. The advantage is that the surface accuracy is high, and the surface after treatment is consistent with the product surface produced by the mold. This truly reflects the product characteristics. The disadvantage is that it takes a long time, because the CNC machine tool needs to write programs and there are many processing procedures, which prolongs the production time; another point is that some parts of the CNC machining center are difficult to process or are not processed properly, and need to be completed manually.

WeLink Tips: The two rapid prototyping processes methods have their own advantages and disadvantages. They can be selected according to actual needs. Try to use CNC prototypes when you need a metal or strong or specific material property plastics. Try to use SLA/SLS 3D printing when you request a 2-3 times assembly, cheap and very short lead time prototype.