How can we benefit from vacuum casting?

When we are going to make prototypes for our new projects, we always look forward to using the most reasonable process to achieve the best quality and the lowest cost. Compared with traditional CNC machining, the new technology 3D printing in recent years has both time and cost advantages in the production of plastic rapid prototypes. So, do we have a better solution for small batches of plastic prototypes?

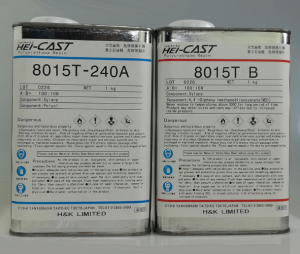

The answer is vacuum casting. In fact, vacuum casting is not a new technology. It was founded in German universities as early as the mid-1960s. After more than half a century of development, it has developed into a room temperature casting technology of dozens of materials. Common materials are ABS, PP, PA, PMMA, Rubber, etc. These materials are liquid. As shown:

What is vacuum casting?

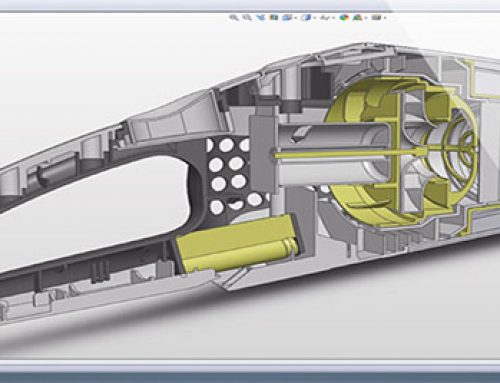

Vacuum casting is to use the existing model (or 3D printing or CNC machining) to reversely make a silicone mold (see figure), and then pour PU (two-component polyurethanes) materials into the vacuum mold cavity at normal temperature and pressure to achieve small batch copy of the original parts.

What are the characteristics and advantages of vacuum casting?

- Short Lead time: 10-20 pieces ofplastic parts can be made in 2-3 days.

- Low cost: onlymake 1 piece ofprototype, the silicone mold is simple, the price is low, the cost is less than 1/3 of CNC machining. And for heavy parts, it is also cheaper than 3D printing.

- Goodquality: Whether it is surface quality or strength, it can be comparable to plastic injectionmolded parts, with 90% performance of the latter.

- For soft rubber parts, neither CNC machining nor 3D printingcould make it out,for small batches, can only choose vacuum casting.

What’s the tolerance of vacuum casting?

±0.3% (with a lower limit on ± 0.3 mm on dimensions smaller than 100 mm)

What’s the max part made of vacuum casting? It depends on the size of the factory’s vacuum casting machine. WeLink can make parts within 1500mm, and larger ones can be made by disassembling parts. If you have any queation about vacuum casting China, welcome to email to quote@welinkgro.com as well as rapid prototyping China.

Based on these characteristics of vacuum casting, will you choose it in your next prototypes?